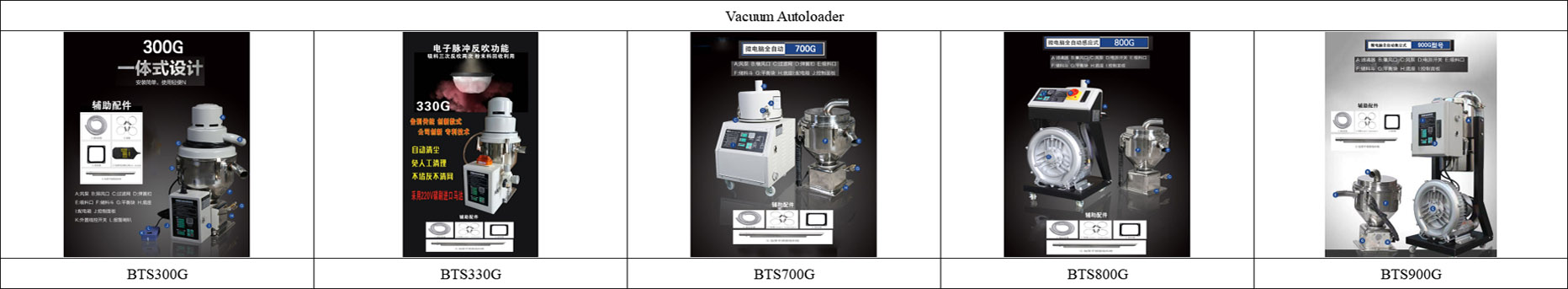

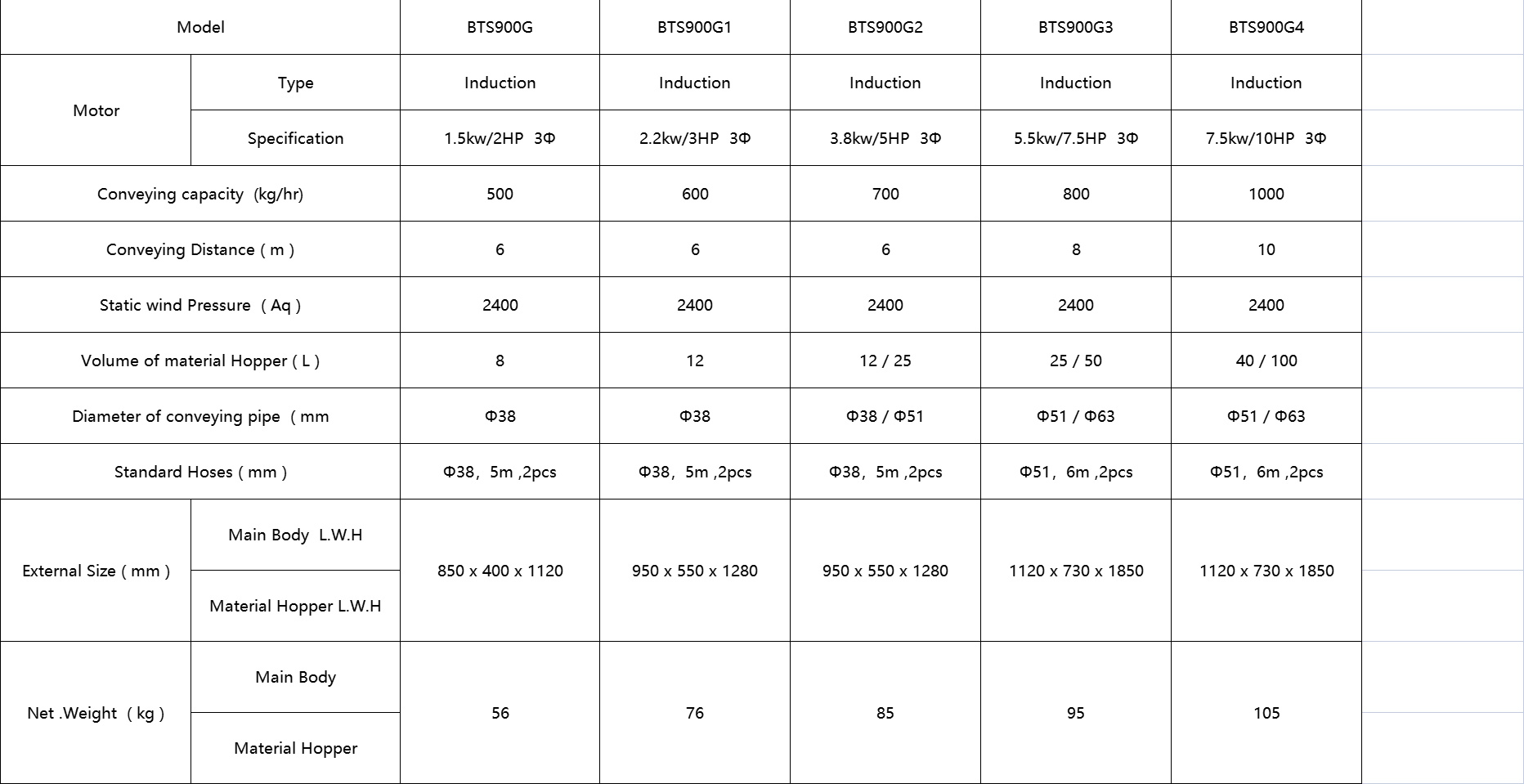

Auto loader

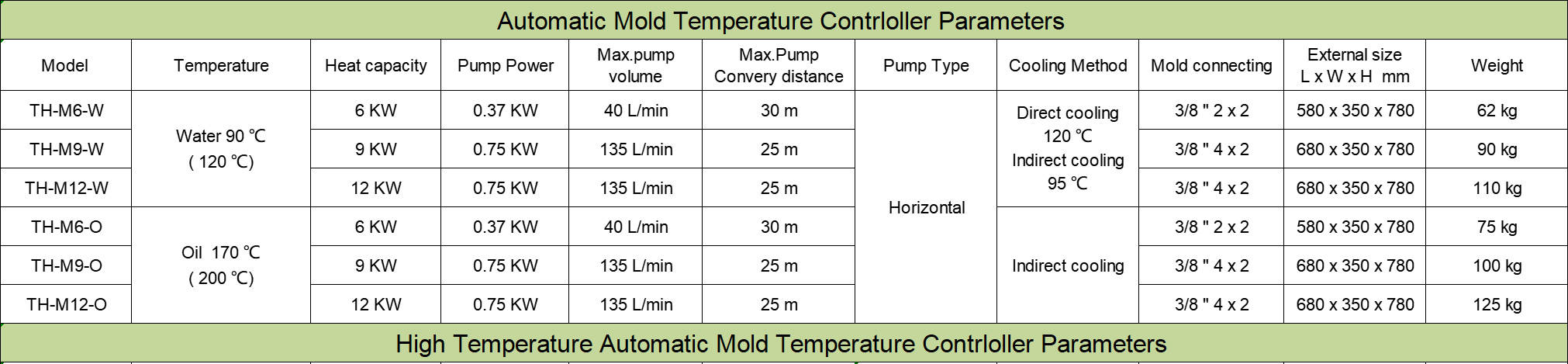

Automatic Mold Temperature Control

Unstable Temperature in the process of mold forming always tends to produce unqualified products, According to the principle of heat exchange . TH-M mold temperature control make use of water and high property heat transferring oil as a medium to keep a properstable temperature in the process of mold forming so as to guarantee high quality of products and raise the productive efficiency.

Unstable Temperature in the process of mold forming always tends to produce unqualified products, According to the principle of heat exchange . TH-M mold temperature control make use of water and high property heat transferring oil as a medium to keep a properstable temperature in the process of mold forming so as to guarantee high quality of products and raise the productive efficiency.

Chiller

| Technical parameter list of water-cooled Chiller. | |||||||||||||

| Model NO. | TH-05WCI | TH-08WCI | TH-10WCI | TH-12WCI | TH-15WCI | TH20WCI | TH-25WCI | TH-30WCI | TH-40WCI | TH-50WCI | TH-60WCI | ||

| Rated Cooling capacity | kw | 16.3 | 26.2 | 34.4 | 39.4 | 52.4 | 68.8 | 78.8 | 103.2 | 140 | 160 | 208.0 | |

| Kcal/h | 14018 | 22532 | 29584 | 33884 | 45064 | 59168 | 67768 | 88752 | 120400 | 137600 | 178880 | ||

| USRT | 4.63 | 7.45 | 9.78 | 11.20 | 14.90 | 19.56 | 22.41 | 29.34 | 39.81 | 45.49 | 59.14 | ||

| COP | 4.9 | 5.2 | 5.2 | 5.3 | 5.2 | 5.2 | 5.3 | 5.2 | 5.3 | 5.3 | 5.1 | ||

| Frozen Medium | Neutral water | ||||||||||||

| Input Power | 380V ,3 Ph , 50HZ | ||||||||||||

| Compressor | Mode | High efficient full -hermetic scroll type compressor | |||||||||||

| Quantity | 1 | 1 | 2 | 1 | 2 | 2 | 2 | 3 | 4 | 4 | 4 | ||

| Input Power | 3.3 | 5 | 6.6 | 7.5 | 10 | 13.2 | 15 | 19.8 | 26.4 | 30 | 40.8 | ||

| Rated load current ( A ) | 7 | 9.9 | 12.7 | 13.8 | 19.8 | 25.4 | 27.6 | 38.1 | 50.8 | 55.6 | 84 | ||

| Matching wire mm2 | 1.5 | 2.5 | 4 | 4 | 6 | 10 | 16 | 16 | 16 | 25 | 25 | ||

| Refrigerant | R22 / R407C / R502 | ||||||||||||

| Water Cooled Condenser | Mode | High efficient outside screwed shell and tube | |||||||||||

| Cooling water Flow m3/h | 3.4 | 5.4 | 7.1 | 8.1 | 10.7 | 14.1 | 16.1 | 24.3 | 28.6 | 32.7 | 42.8 | ||

| Cooling water Temperature ℃ | Inlet 30 ℃ / Outlet 35 ℃ | ||||||||||||

| Pump | Power (kw) | 0.37 | 0.75 | 0.75 | 0.75 | 1.5 | 1.5 | 2.2 | 2.2 | 3 | 3 | 4 | |

| Flow (L/min) | 1.2 | 1.2 | 1.2 | 1.2 | 6.0 | 6.0 | 6.0 | 6.0 | 30.0 | 30.0 | 50.0 | ||

| Max.Pump head (m ) | 17.7 | 28.2 | 28.2 | 28.2 | 23.2 | 23.2 | 28.2 | 28.2 | 19.0 | 19.0 | 18.0 | ||

| Evaporator | Mode | High efficient intside screwed shell and tube / water tank Immersion ( up 10HP ) | |||||||||||

| Ice water flow m3/h | 2.8 | 4.5 | 5.9 | 6.8 | 9.0 | 11.8 | 13.6 | 17.8 | 24.1 | 27.5 | 35.8 | ||

| Ice water inlet & outlet Temperature ℃ | Inlet 20 ℃/ Outlet 15 ℃ | ||||||||||||

| Throttle Methods | External balance expansion valve | ||||||||||||

| Safety Protection | 1.Water Pump interlock protection / 2. leakage protection / 3.overload protection / 4. overpressure and anti-phase protection / 5. refrigerant abnormality protection / 6. compressor over temperature protection / 7. and lack of water protection / |

||||||||||||

| Piping Connetion | Cooling water in&outlet diameter | Ø 32 | Ø 50 | Ø 50 | Ø 50 | Ø 63 | Ø 63 | Ø 63 | Ø 63 | Ø 76 | Ø 76 | Ø 89 | |

| Ice water in&outlet diameter | Ø 32 | Ø 50 | Ø 50 | Ø 50 | Ø 63 | Ø 63 | Ø 63 | Ø 63 | Ø 76 | Ø 76 | Ø 89 | ||

| Weight kg | 130 | 200 | 230 | 260 | 300 | 400 | 500 | 630 | 950 | 1260 | 1600 | ||

| Size L.W.H mm | 1200 x 750 x 1100 | 1200 x 750 x 1100 | 1350 x 750 x 1150 | 1350 x 750 x 1150 | 1750 x 800 x 1300 | 1750 x 800 x 1300 | 2000 x 950 x 1300 | 2000 x 950 x 1300 | 2300 x 1000 x 1450 | 2600 x 1000 x 1600 | 2900 x 1200 x 1800 | ||

| Remark: 1. Working conditions : Chilled water Temperature 20 ℃ \ 15 ℃ . 2.The Product dimensions are based on the actual product, and the technical parameters have been changed due to product improvement,Without notice. |

|||||||||||||

| Technical parameter List of Air-cooled Chiller | ||||||||||||||

| Model NO. | TH-03ACI | TH-05ACI | TH-08ACI | TH-10ACI | TH-12ACI | TH-15ACI | TH20ACI | TH-25ACI | TH-30ACI | TH-40ACI | TH-50ACI | TH-60ACI | ||

| Rated Cooling capacity | kw | 9 | 15 | 23.6 | 31.2 | 35.5 | 47.2 | 62.4 | 71 | 92.0 | 128.0 | 144.0 | 184.0 | |

| Kcal/h | 7740 | 12900 | 20296 | 26832 | 30530 | 40592 | 53664 | 61060 | 79120 | 110080 | 123840 | 158240 | ||

| USRT | 2.6 | 4.3 | 6.7 | 8.9 | 10.1 | 13.4 | 17.7 | 20.2 | 26.2 | 36.4 | 40.9 | 52.3 | ||

| COP | 3.8 | 3.8 | 3.9 | 3.9 | 3.9 | 3.9 | 3.9 | 3.9 | 3.7 | 4.0 | 3.9 | 3.7 | ||

| Frozen Medium | Neutral water | |||||||||||||

| Input Power | 380V ,3 Ph , 50HZ | |||||||||||||

| Compressor | Mode | High efficient full -hermetic scroll type compressor | ||||||||||||

| Quantity | 1 | 1 | 1 | 2 | 1 | 2 | 2 | 2 | 3 | 4 | 4 | 4 | ||

| Input Power (KW) | 2.4 | 4 | 6.1 | 8.1 | 9.2 | 12.2 | 16.2 | 18.4 | 24.8 | 32.4 | 36.8 | 49.6 | ||

| Rated load current ( A ) | 4.4 | 7.8 | 11.6 | 14.6 | 16.2 | 23.2 | 29.2 | 32.4 | 47.8 | 58.4 | 64.8 | 95.6 | ||

| Matching wire mm2 | 1.5 | 1.5 | 2.5 | 4 | 4 | 6 | 10 | 16 | 16 | 16 | 25 | 25 | ||

| Refrigerant | R22 / R407C / R502 | |||||||||||||

| Air Cooled Condenser | Mode | High efficient intside screw tube shinizu fin style | ||||||||||||

| Heat exchange Area / m2 | 30 | 50 | 80 | 100 | 120 | 160 | 200 | 250 | 300 | 400 | 500 | 600 | ||

| Cooling Method / Cooling Fan Power: W | 180 | 250 | 500 | 900 | 900 | 1200 | 1200 | 1800 | 1800 | 3400 | 4800 | 5100 | ||

| Pump | Power (kw) | 0.37 | 0.37 | 0.75 | 0.75 | 0.75 | 1.5 | 1.5 | 2.2 | 2.2 | 3 | 3 | 3 | |

| Flow (m3/h) | 1.2 | 1.2 | 1.2 | 1.2 | 1.2 | 6.0 | 6.0 | 6.0 | 6.0 | 30.0 | 30.0 | 50.0 | ||

| Max.Pump head (m ) | 17.7 | 17.7 | 28.2 | 28.2 | 28.2 | 23.2 | 23.2 | 28.2 | 28.2 | 19.0 | 19.0 | 13.0 | ||

| Evaporator | Mode | Coil form | High efficient inside screwed shell and tube / water tank immersion ( up to 10HP) | |||||||||||

| Ice water flow m3/h | 1.5 | 2.6 | 4.1 | 5.4 | 6.1 | 8.1 | 10.7 | 12.2 | 15.8 | 22.0 | 24.8 | 31.6 | ||

| Ice water inlet & outlet Temperature ℃ | Inlet 20 ℃/ Outlet 15℃ | |||||||||||||

| Throttle Methods | External balance expansion valve | |||||||||||||

| Safety Protection | 1.Water Pump interlock protection / 2. leakage protection / 3.overload protection / 4. overpressure and anti-phase protection / 5. refrigerant abnormality protection / 6. compressor over temperature protection / 7. lack of water protection / |

|||||||||||||

| Piping Connetion | Ice water in&outlet diameter | Ø 32 | Ø 32 | Ø 50 | Ø 50 | Ø 50 | Ø 63 | Ø 63 | Ø 63 | Ø 63 | Ø 76 | Ø 76 | Ø 89 | |

| Weight kg | 220 | 240 | 335 | 430 | 550 | 630 | 790 | 880 | 1260 | 1680 | 2110 | 2520 | ||

| Size L.W.H mm | 950 x 700 x 1200 | 1100 x 750 x 1300 | 1500 x 750 x 1350 | 1550 x 820 x 1300 | 1750 x 820 x 1300 | 1900 x 950 x 1400 | 1950 x 1050 x 1540 | 2500 x 1000 x 1500 | 2650 x 1050 x 1540 | 2810 x 1200 x 1650 | 2950 x 1250 x 1720 | 3100 x 1400 x 1850 | ||

| Remark: 1. Working conditions : Chilled water Temperature 20 ℃ \ 15 ℃ . 2.The Product dimensions are based on the actual product, and the technical parameters have been changed due to product improvement,Without notice. |

||||||||||||||

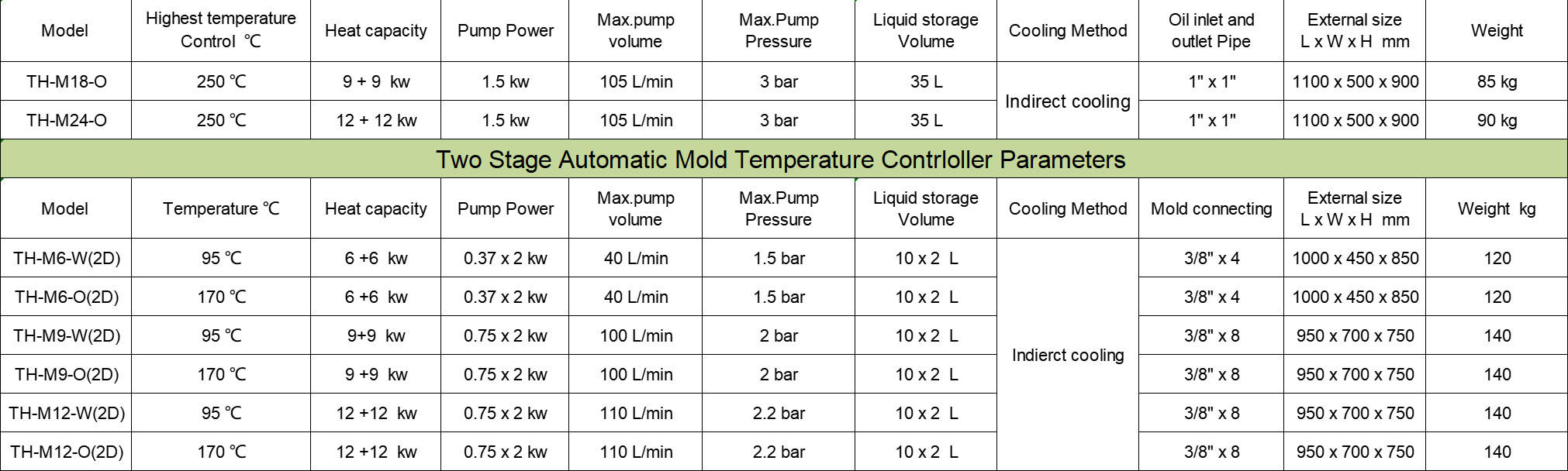

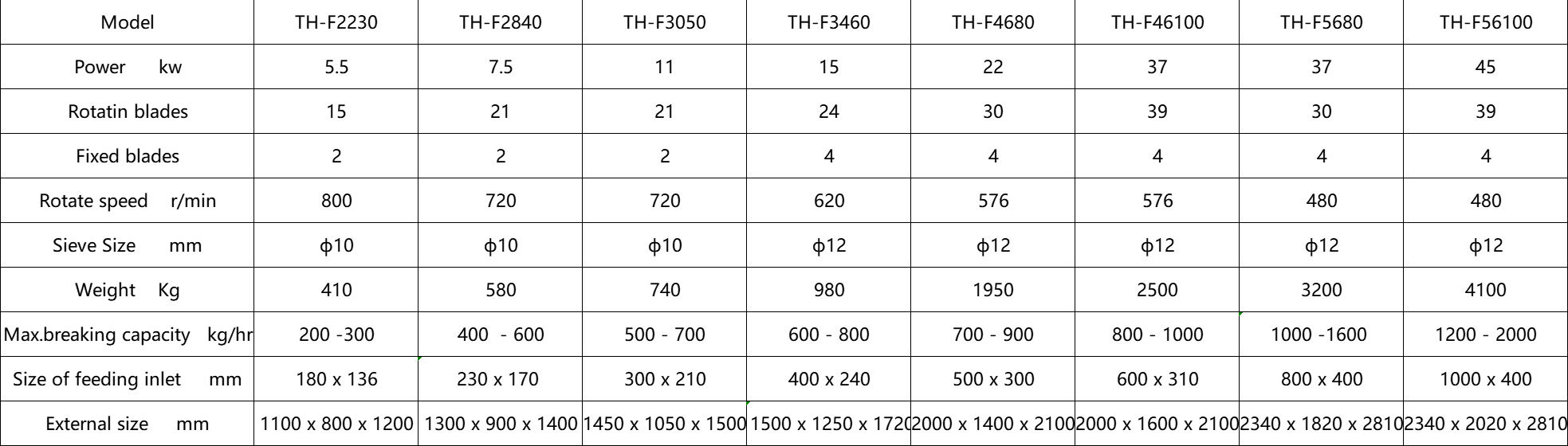

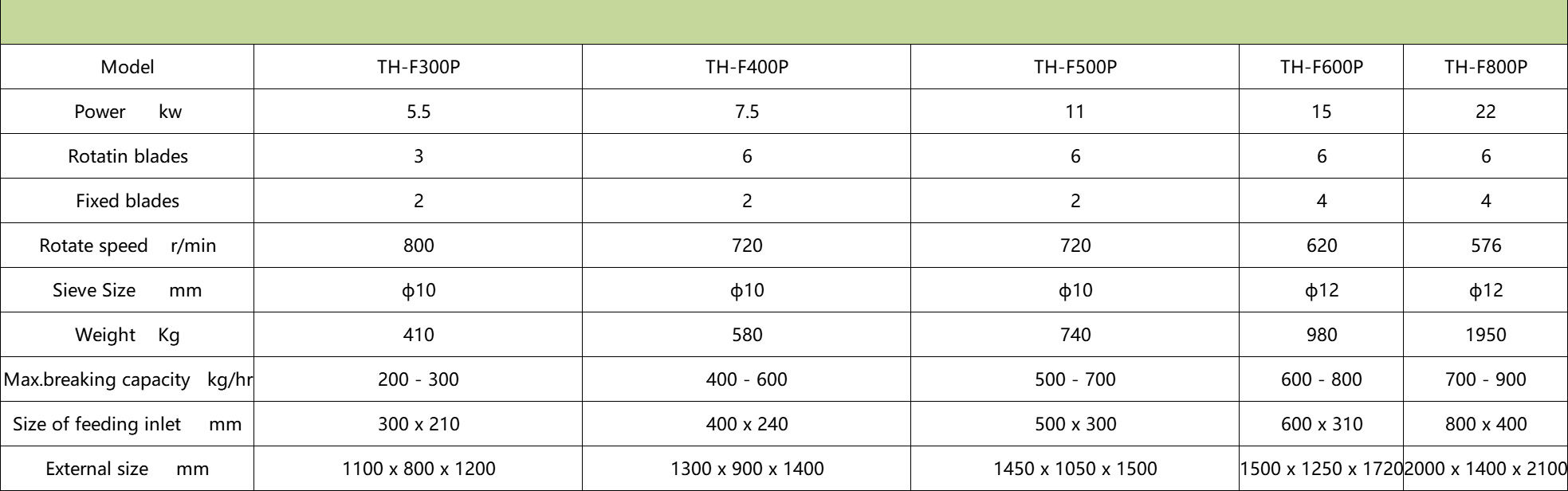

Crusher

Check Out The Plastic Crusher Granulator Mill From Threeplast Machinery

Plastic crushers play a crucial part in the recycling production and plants facilities. The machines provide many advantages in addition to processing all the plastic-related items. These plastics are used in raw materials for various other products, such as consumer electronics, storage containers, packaging bags, and toys.

Companies will find many plastics crushing machines available in the market but will not find those offered by Threeplast Machinery. We wear the crown of the best plastic crusher granulator mill supplier in the market. Our industrial plastic crushing machine will help reduce the size and help recoup waste plastic.

Plastic Crusher Machine: Things to Know

Being a well-known plastic crusher granulator mill supplier, we have created crushers that will stand out as indispensable elements of cost-effective and efficient operations in the waste and recycling management sector. Our team of experienced engineers has designed these machines to shred down a diverse range of plastics.

The machine comes with a low to moderate speed along with high torque. All our interested customers will come across various models of plastic crushers and each of their blade sizes and specifications. We have plastic crushers that range from single shaft machines to the highly-advanced machines for shafts mechanism.

The four shaft machines contain cutters, grinders, hammers, and of course, granulators. But that's not all, and our machines also contain the shaking and sorting functionality.

The Features Of The Plastic Crushers

We have listed down the features of our plastic crushers, which help our customers to have a good idea of what our machines are capable of. We, one of the top Plastic crusher granulator mill supplier, provide plastic crusher that contains high-intensity steel screws that help fasten the knife seat and knife lead, and this provides the machine with a strong bearing capacity.

The walls of the machines are made from sound-proof materials, which will lessen the noise when it's in use.

The sieve present inside the machine can be easily dismounted to clean it easily, and one can place it back with no hassle.

Threeplast Machinery - The Best Plastic Crusher Granulator Mill Supplier

We from Threeplast Machinery can offer our customers a plastic crusher that will match perfectly with requirements. Each model is different, and we will ship the machine to the country where our customer is located.

"The knife tool is refined with imported special tool-steel. the clearance between knife tools are adjustable . when it becomes blunt by using , it can be dismounted repeatedlly . it is Durable ."

1.Use high-intensity steel screws to fasten the knife leaf and knife seat , having strong bearing capacity .

2. All walls of crushing chamber are treated by sound-proof, so having extra-low noise

3. A disconnect-type designed , the bunker, main body, Sieve can be dismounted for cleaning easily, heavey bearing with dust protection device .

4. The Motor has over-loading protection with power source interlock protection device . Double- safely protection for operatiorand motor .

5. Step-type motion knife design with strong breaking capacity.

6. Equipped vibration feet on TH-F500, Reduce noise of vibration .

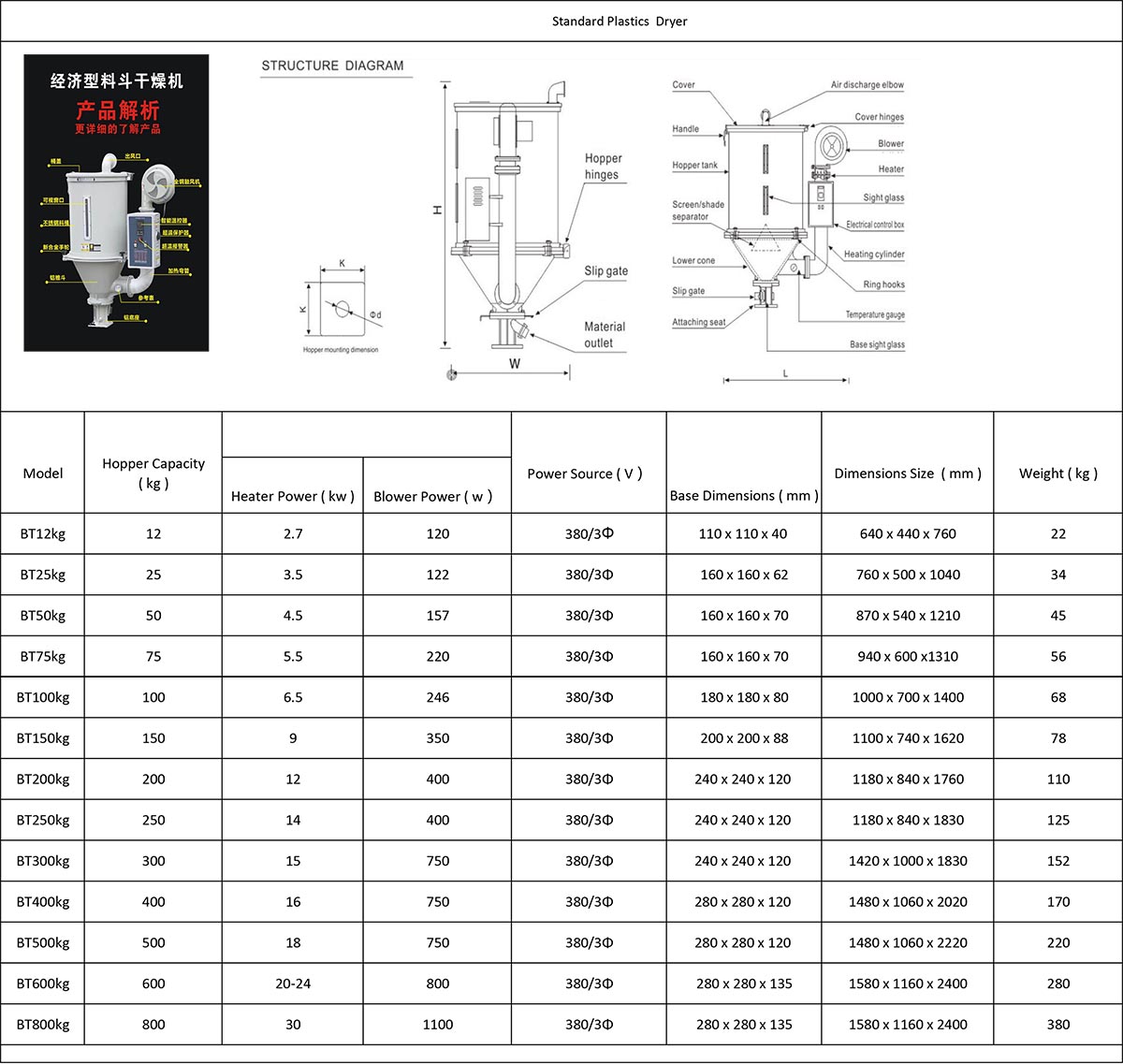

Hopper Dryer

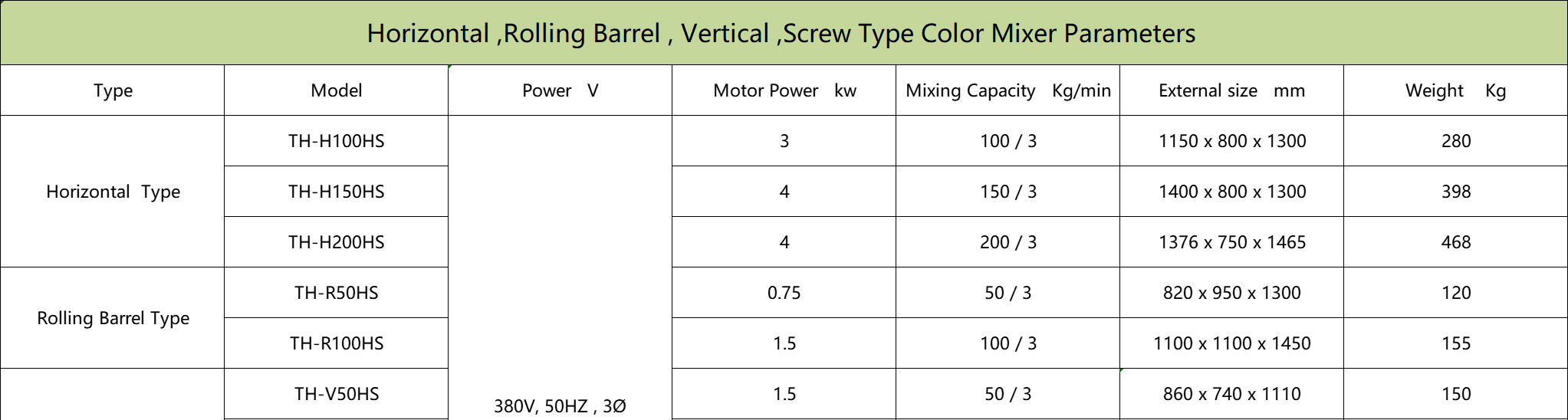

Mixer