Universal Series - Servo Motor Energy Saving Injection Molding Machine

This SERVO injection molding machine is designed for your Universal Processing applications this series of machinery is fast, accurate and has Excellent Repeatability. THREEPLAST Servo motor energy saving injection molding machine can help you reach a maximum producibility on a wide range of materials. with a Nitrided +Alloy screw & barrel. wear-resistant screw tip. High strength tie-bars and rigid platens. It all adds up to a unit, that will stay the course. Our Servo motor energy saving injection molding machine gives consistently high quality and output with a wide range of materials and with the most complex of molds.

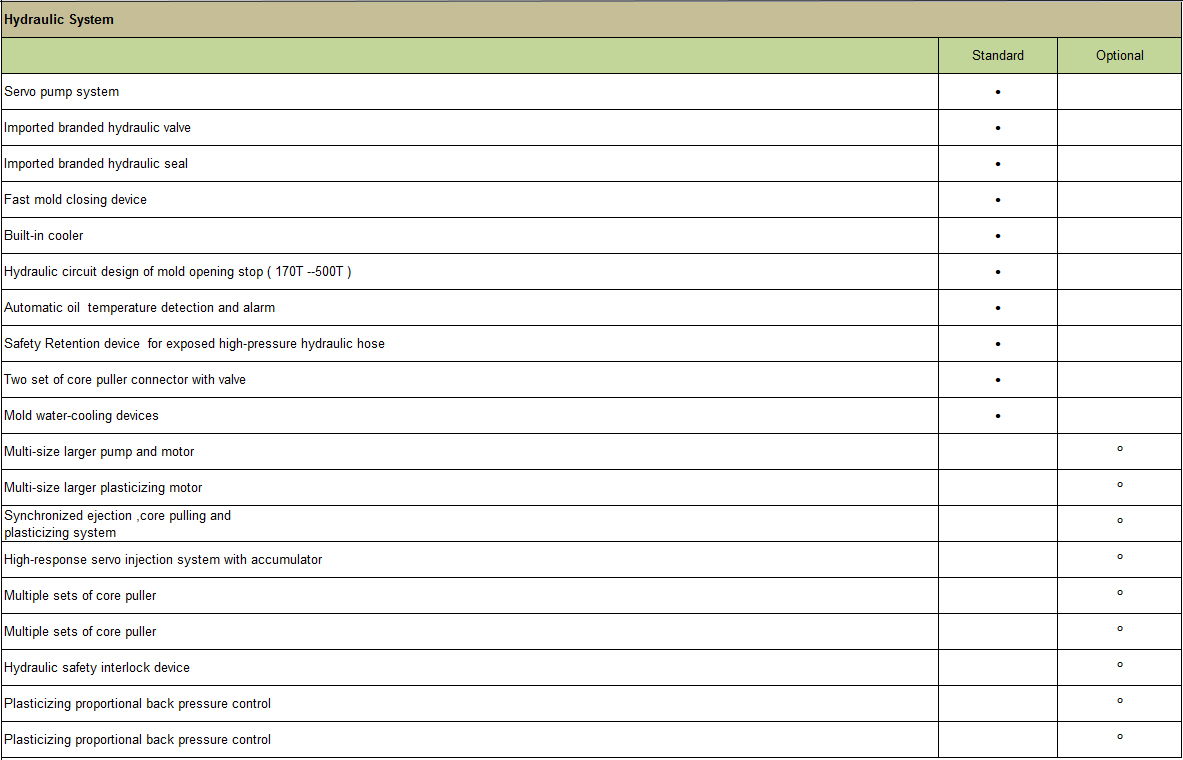

High Speed Valve Response, reliable continual operation and optimum energy savings.

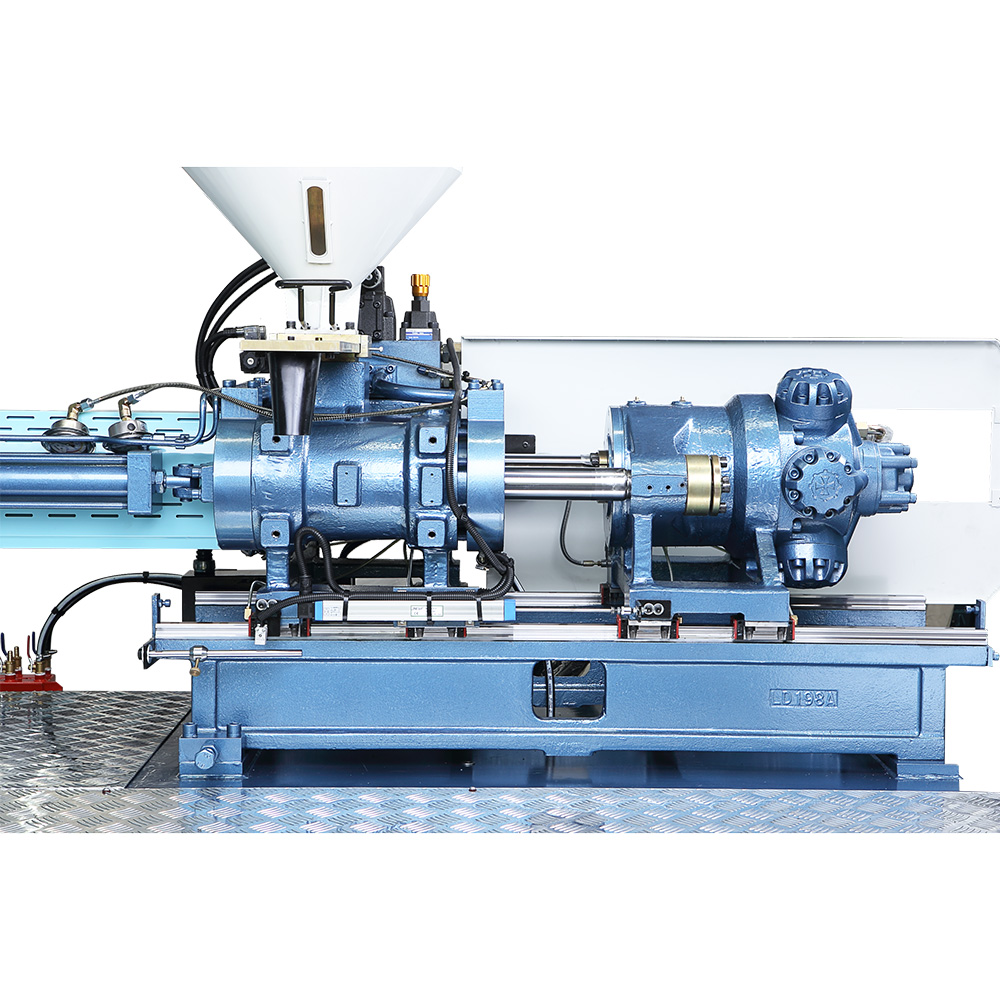

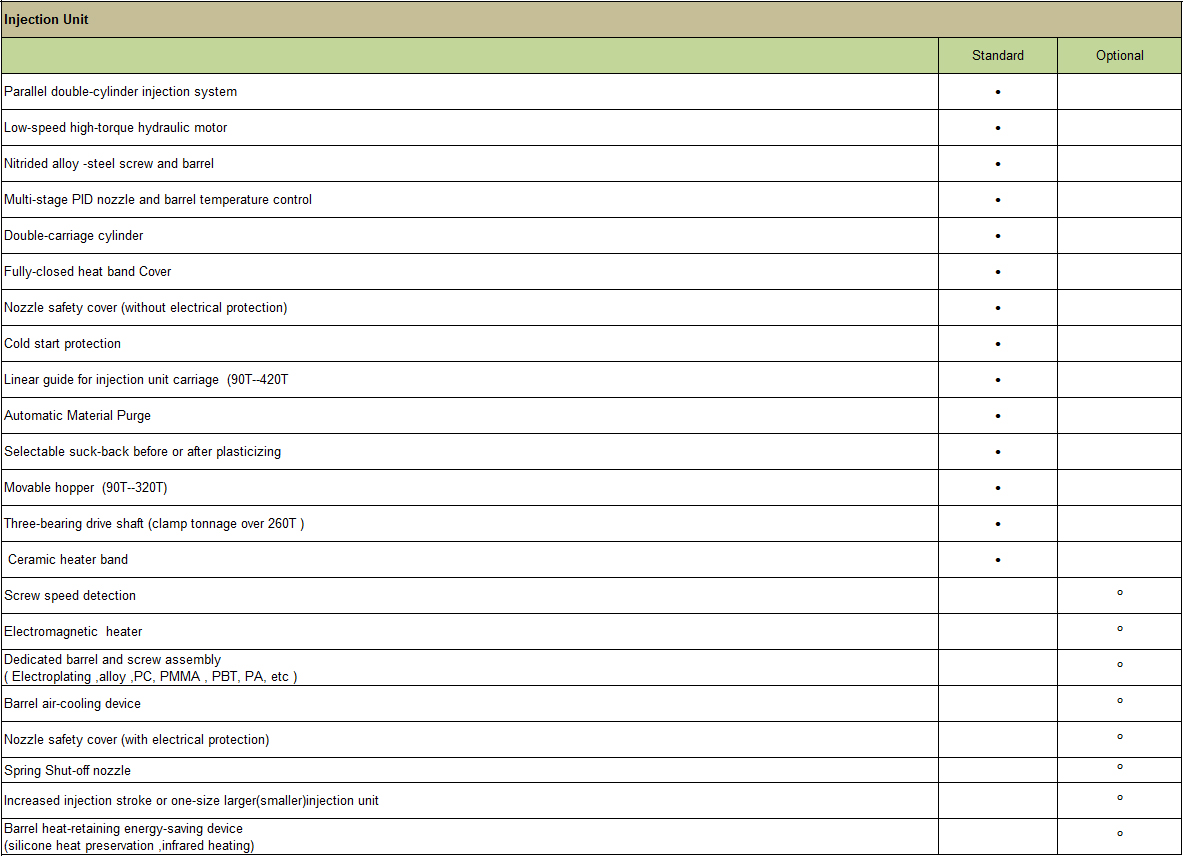

Excellent Wear-Resistant,corrosion resistant screw & barrel for the processing of materials with fiber additives and also fire retardant materials.

Screw Driven by high torque,variable speed ,radial piston motor.

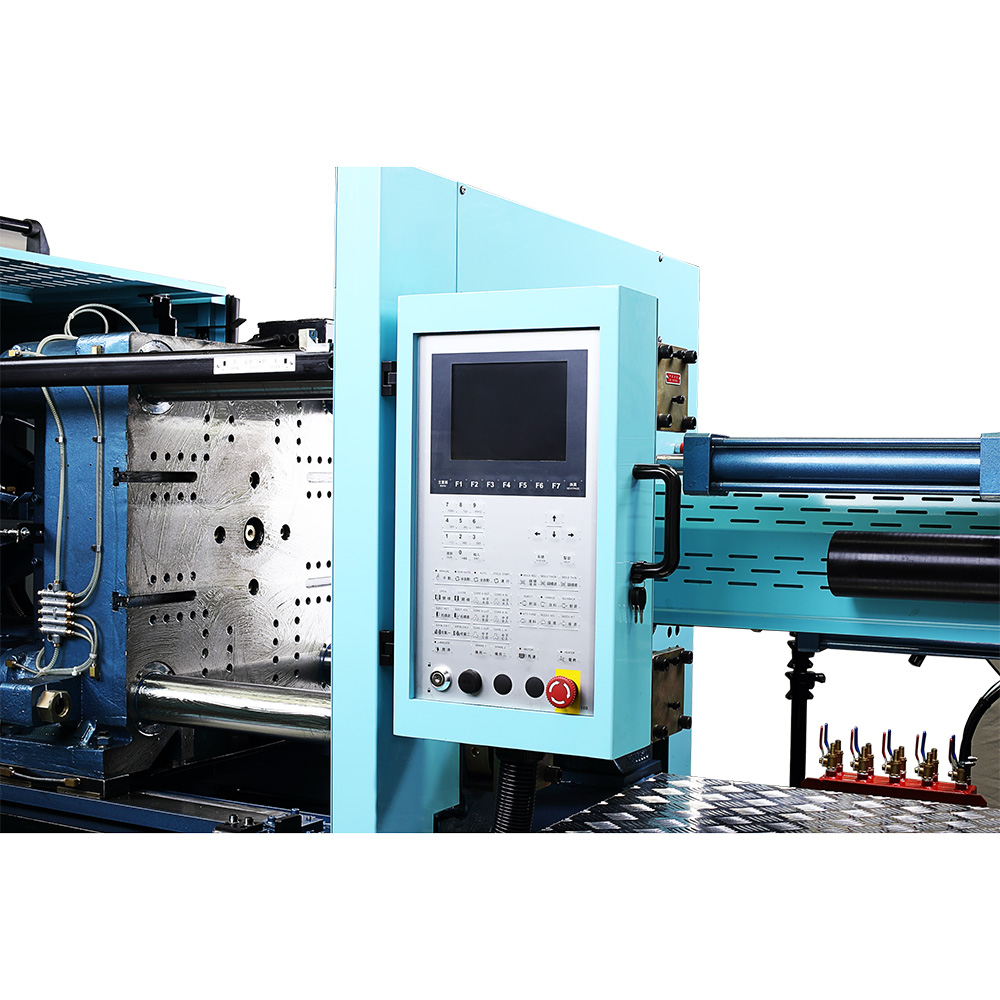

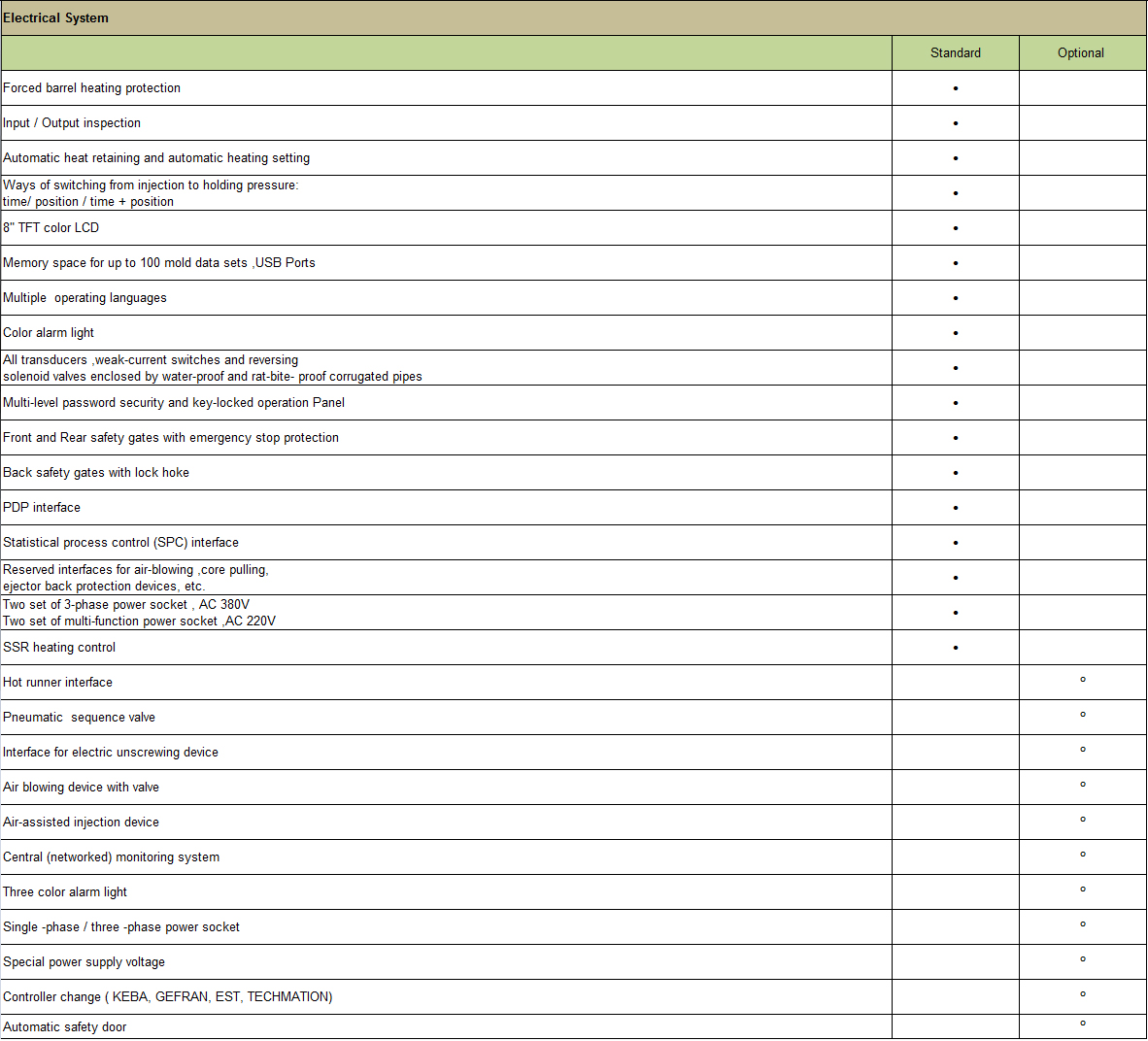

PID Temperature Control insures an accuracy of +/-1℃, thus the fluctuation of the temperature is very minimal. Cushion Monitoring can help the operator to check the quality of the product. Ie if the injection end position is under the allowed tolerance that means that the product is within necessary required quality.

Proportional Valve control for pressure and volume settings.

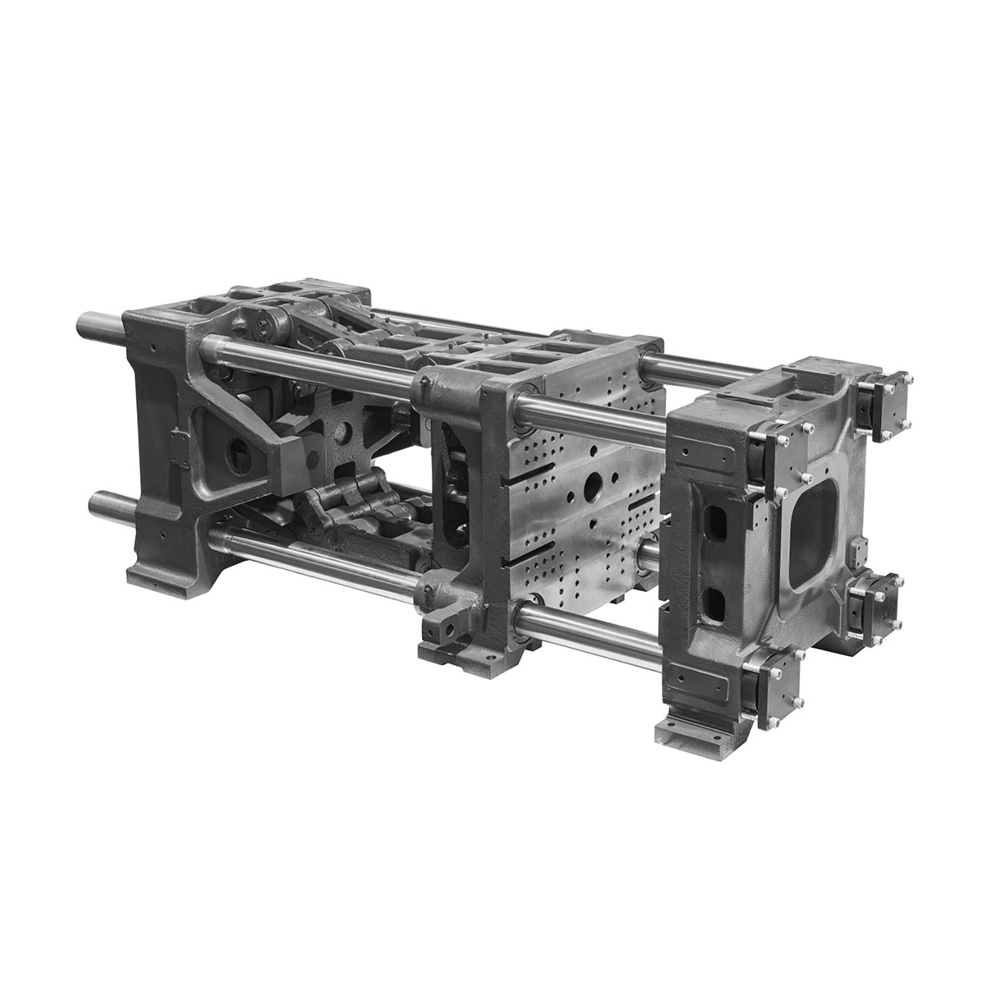

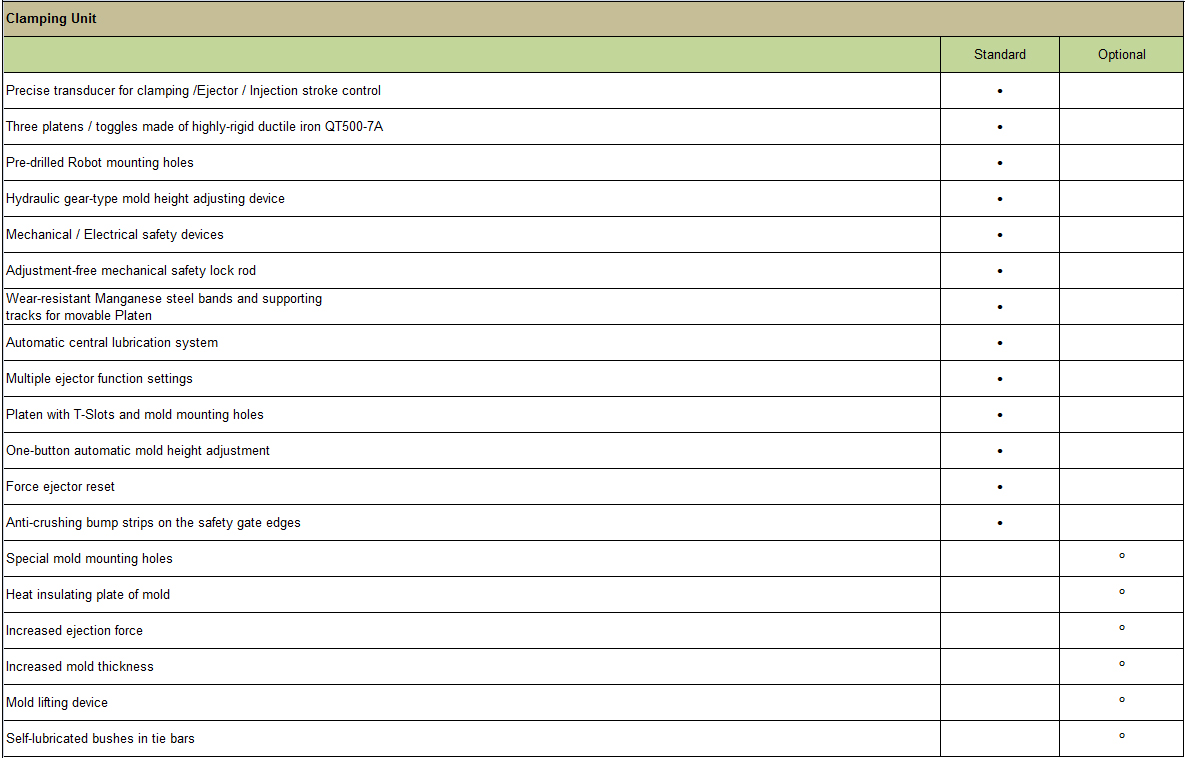

Unique, Ultra Reliable. Five point toggle clamping mechanism which is characterized by an almost ideal kinematic velocity feature.

Mold opening and closing speed are digitally set in 4 stages, each with variable adjustment on pressure, volume and position.

Injection Speed profiles digitally set at 5 selectable stages by time or distance. Holding pressure by 4 stages and charging by 6 stages.

Contact us for SERVO energy saving injection molding machines at best price today!